AnkerMake M5C Review: Fast 3D Printing, No Screen

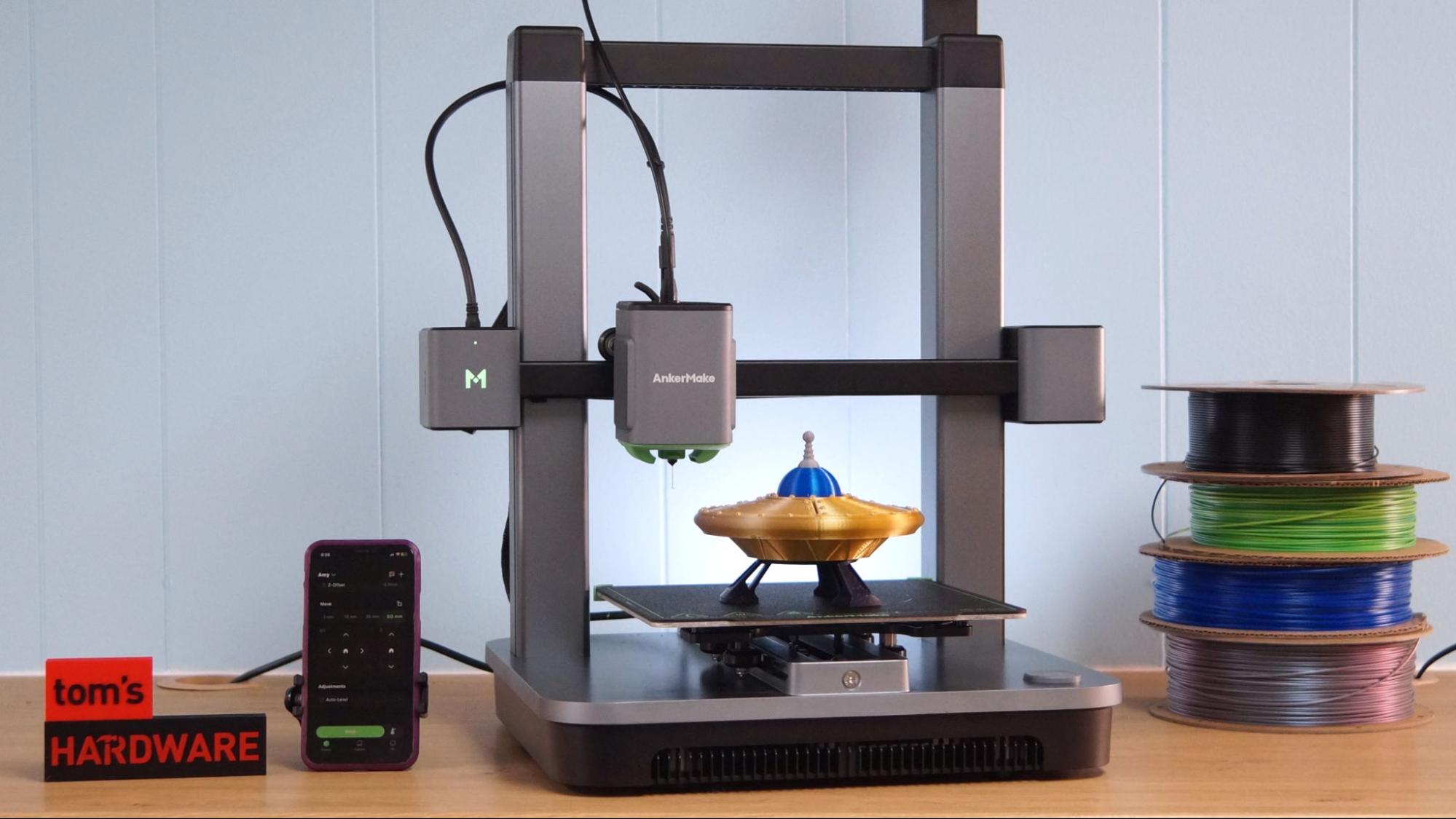

In 2022, Anker surprised everyone with the remarkably fast AnkerMake M5, a premium bedslinger with AI print monitoring. Unfortunately, it had its thunder stolen by an even faster Core XY from Bambu Lab. After a minor course correction, Anker is back with the M5C: a faster, cheaper, and more user-friendly 3D printer.

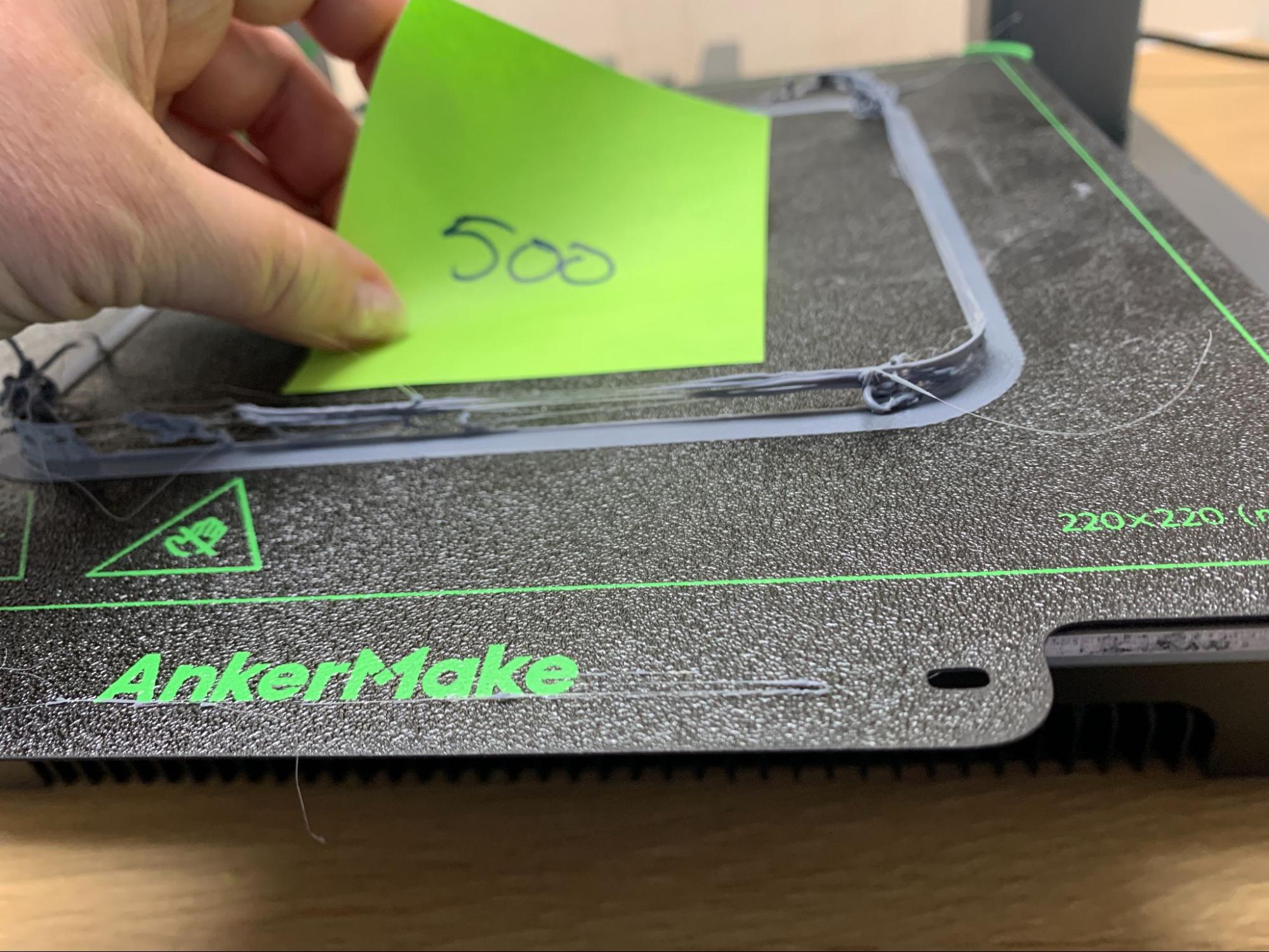

Retailing at $399, the M5C boasts a 500 mm/s top speed with an all metal hotend capable of burning through filament at 300 degrees Celsius. It’s a bit smaller, with an Ender sized 220 x 220 build plate.

One obvious thing is missing, and that’s the screen. Anker made a very interesting decision to completely remove any kind of display from the M5C, favoring a giant “play” button and a phone app. Phone apps for 3D printers are nothing new, but these are normally bonus features for monitoring your prints. AnkerMake’s phone app is required and it’s the only way to fully control your printer. This may trouble users of a certain age, while also appealing to those who grew up with technology in their pocket.

Anker’s marketing department is leaning heavily on the printer’s appeal to first time users with ads (and several sponsored YouTube videos) calling attention to the singular play button. This is a little misleading, as Anker only has 37 ready to go prints you can “play” from the app as of this writing. For everything else you’ll still need to use a computer based slicer, and since Anker doesn’t provide a USB-C stick for the printer, you’re more likely to send files via WiFi and avoid the play button entirely.

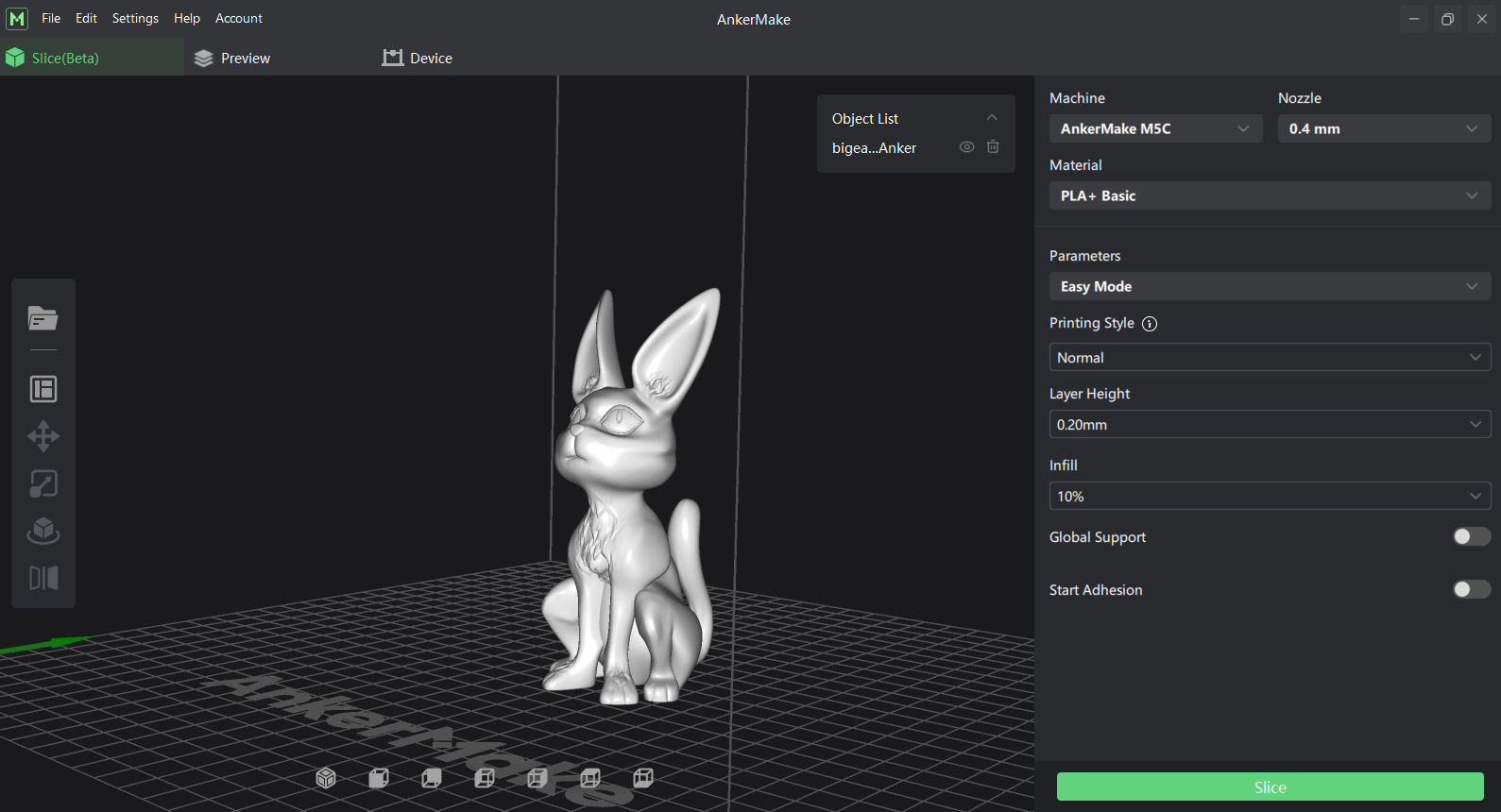

The AnkerMake slicer received a thorough overhaul and is the cornerstone of this printer’s easy-peasy experience. Users are encouraged to stick to the Easy mode, which hides all the complex slicer settings. We tried the Easy setting for most of our test prints and found that the presets are very reliable with a wide range of usable filament settings.

We do have some concerns about relying on a mobile app to control a 3D printer, mainly being the annoyance of forgetting to bring your phone when you want to change the filament and the trouble involved with sharing the printer. For example, if I want other members of my family to be able to control the printer they will need to download the app and make an account – or grab my phone. Of course, this could be seen as a plus. If the printer were used by a school, library or maker space the only people who could fully operate the machine are those with access to the mobile app.

Overall, the AnkerMake M5C is a solid performer that delivers speed and ease of use, making it one of the best 3D printers.

Specifications: AnkerMake M5C

| Build Volume | 220 x 220 x 250 mm (8.6 x 8.6 x 9.8 inches) |

| Material | PLA/PETG/TPU (up to 300 degrees) |

| Extruder Type | Direct Drive |

| Nozzle | .4 high flow |

| Build Platform | PEI textured spring steel sheet, heated |

| Bed Leveling | Automatic |

| Filament Runout Sensor | Yes |

| Connectivity | WiFi, Bluetooth, USB-C |

| Interface | One Button |

| Machine Footprint | 466×374×480 mm (18.3 x 14.7 x 18.8in) |

| Machine Weight | 9.6 KG (21.1 lbs) |

Included in the box: AnkerMake M5C

The AnkerMake M5C comes with all the parts you need to get started: tools in a handy kit to build and maintain the printer which includes a pair of side cutters. You also get a spare nozzle. Oddly missing is a sample of filament for your first print, so be sure to buy some when you order the printer. We maintain a list of the best filaments for 3D printing to help you choose.

There’s a poster with a quickstart guide to help you build and set up the printer. At the time of publication there were 37 pre-sliced prints included on the AnkerMake app, which you need to download in order to run this printer.

Assembling the AnkerMake M5C

The AnkerMake M5C arrives mostly pre-assembled and only needs 8 bolts – four for each side – to put together. I got it assembled in about 20 minutes. The wiring is easier than most printers with just two sets of wires for the stepper motors, then a single appliance style cord to plug into the tool head.

Leveling the AnkerMake M5C

The AnkerMake M5C has a pressure sensor mechanism connected to the hotend for automatic bed leveling. This is my favorite method of bed leveling, as it physically taps the surface and often sets a perfect Z height in the process. On this printer, the z height only needed to be adjusted for printing PETG.

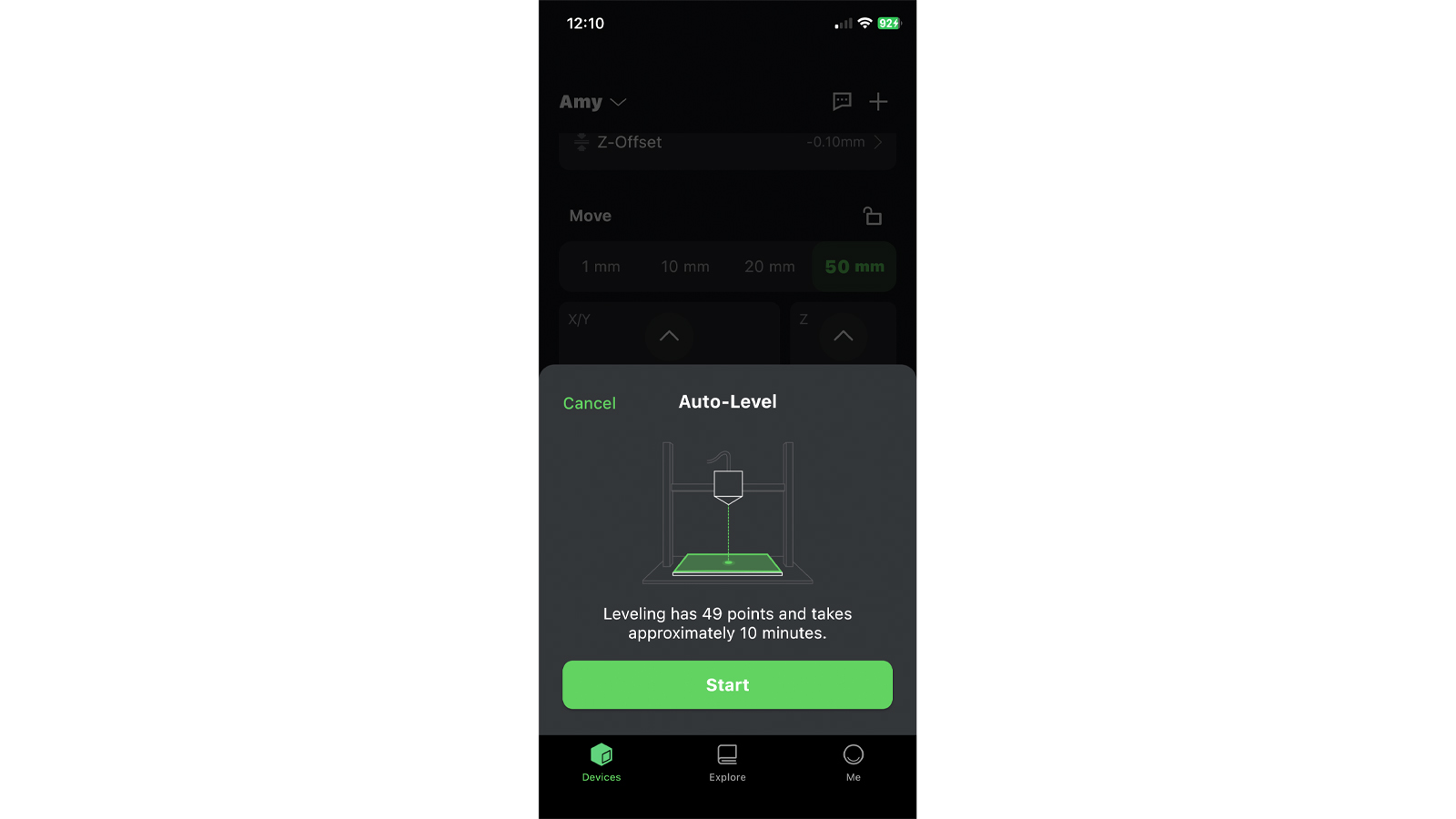

The build platform is hard mounted to the Y-Axis and there are no knobs for manual tramming. Everything is done through the app.

To level the bed, scroll down the app until you see Adjustments and press the Auto Level button. The app will inform you that leveling will take about 10 minutes. Press Start to continue and the machine will warm up to 175 degrees on the nozzle and 60 degrees on the bed. It will then home and double tap 49 spots in a 7×7 in a grid across the bed surface.

Loading Filament in the AnkerMake M5C

The AnkerMake M5C has an improved filament path with a reverse Bowden tube connected to the spool holder. This allows easy feeding directly into the extruder.

To load filament, tap the thermometer icon next to the Print button. Select the type of filament you are loading from the list and it will warm the nozzle and plate appropriately. Push the filament into the Bowden tube until you meet resistance. Push the lever on the tool head and push the filament in an extra few millimeters. Now click Extrude from the main screen and it will feed the filament into the hotend.

To remove filament or change colors, reverse the process.

Design of the AnkerMake M5C

The AnkerMake M5C is a more compact version of the AnkerMake M5, with a similar polished modern appearance. The wiring and mechanics are neatly concealed within the printer’s frame, with only a single exposed cable running to the tool head.

The printer has no screen or control panel, and must use a mobile app or computer to operate it. The printer’s biggest feature is the large play button on the front right corner of the base and a glowing LED “M” on the gantry.

AnkerMake is making a big deal out of the “one touch button” on the M5C, but it’s more of a gimmick than anything revolutionary. The button is programmable (from the app, of course) and can do a limited set of functions. You can program it to do five things – three when idle, two when printing. The button performs these actions when you tap it once, double tap and press for 3 seconds.

While idle, you can have the button:

- Print the latest file on the USB-C drive

- Reprint the last file

- Auto-level

- Home all axis

- Do Nothing

While printing, the button can

- Pause/Continue

- Stop Printing

- Do Nothing

The button is useful as an emergency stop, or to pause the printer for a filament swap. But since the printer doesn’t come with a USB-C flash drive (an unusual format I don’t own) I wasn’t able to test “playing” a file from the memory stick. I was able to reprint the last file using the button, which is somewhat helpful.

When you send a pre-sliced file from the mobile app there’s no need to push the button – the app does all the work. When you send files over WiFi from the AnkerMake slicer, there’s also no need to push the button.

With all this emphasis on a mobile app, the AnkerMake M5C could really use a camera. The M5 had one, and it seems strange to have to make visual contact with a machine to verify the print bed is clear when you could – in theory – start a print from anywhere in the world.

Despite the lack of a camera, the app is remarkably useful. When the printer runs into problems, it can alert you right away. When I tested the filament runout sensor, the app pinged my phone and told me it needed filament. I unplugged the tool head without turning off the power (to photograph the interior) causing the machine to throw a major error – it could no longer sense the printer’s temperature. It alerted me to this potentially dangerous problem with loud beeping, a warning from my app, AND an email.

The AnkerMake app is home to a growing number of pre-sliced files. The files are all small enough to fit the M5C, and are compatible with the M5. As of this posting, the app has 37 files that are mostly toys. This is nowhere near the level of ToyBox’s app, but there’s no saying how much the library may grow. I’m not seeing a way to add your own files to the library, though perhaps that is something that could be done if I had a USB-C stick. There is no file storage on the printer itself.

The AnkerMake app can also be used with the older M5, and can run several printers simultaneously.

The M5C may be smaller than the M5, and doesn’t have a camera with AI, but that doesn’t make it an inferior product. It has a better all metal hotend, capable of reaching 300 degrees and a higher flow rate (35mm³ vs 24mm³), the filament runout sensor is on the tool head where it’s less annoying and the Y belt isn’t stuck in a crevasse where filament scraps can get tangled. It’s also a little more quiet than the M5, but not as quiet as a slower printer.

The M5C is extremely fast without needing all the weight of the previous machine to hold it steady. In April, the company released a firmware update for the M5, stating that Klipper’s Pressure Advance and Input Shaper had been integrated, which doubled that printer’s top speed to 500mm/s. The new limits are standard on the M5C, which also seems better tuned and produces cleaner prints at high speed.

AnkerMake is sticking to its proprietary high flow nozzle that you’ll need to purchase from their website. You get 10 for $20, which is a tad high for brass nozzles, but you can get different sizes, from .2 to .8mm.

Preparing Files / Software

AnkerMake has its own custom slicer, which has seen a major overhaul since the launch of the M5. I’m normally not a big fan of proprietary slicers, but I’ll make an exception for this one. Though other slicers have Easy or Basic modes, the one for AnkerMake actually works well because of the simple layout. You work your way from top to bottom selecting Printer, Material, Printing Style (speed), Layer Height and so forth. Everything is limited to a Yes/No or maximum choice of three options.

Click Slice and send to the Preview Menu – which is the same screen you’d see on Expert Mode. Here you can double check the slicing. Click Export to save the file – perhaps to that elusive USB-C flash drive – or click Print and send it right to a printer. It still goes through the motions of creating an AI image, which is only used for the M5 and its camera. This might be misleading to M5C owners – or a future upgrade?

Printing on the AnkerMake M5C

The AnkerMake M5C has a top speed of 500mm/s, but you’ll get higher quality if you stick to 250mm/s – not too shabby. I did a lot of speed testing, and though 500mm/s is a bit of a reach, there were never any quality issues due to vibration.

My test prints came from the AnkerMake app, and since the machine didn’t come with any filament, I used samples of EIBOS Matte-PLA. You’ll definitely want to shop for filament before bringing this machine home. We have a guide with our favorite filaments for 3D printing here.

The gray cat/bunny on the right was printed directly from the app and defaulted to “fast printing.” It looks a little rough and the chin suffered from lack of supports. The one in the middle I sliced myself, still using default “normal” speeds, but I bumped up the walls to three – and removed the brim – which increased the quality of the print.

The khaki bunny on the left used the same settings but was sent to the AnkerMake M5. The print has slightly less quality than the sliced M5C print, with somewhat rough layers. The print took 30 minutes to print from the app, and 50 minutes and 21 seconds to print with 3 walls at 250 mm/s.

I ran an amazingly fast 20 minute 4 second Benchy using Speed Boat Rules (2 walls, 3 top and bottom layers, 10% grid infill, a .25 layer height and .5 layer width). The layers are rough, but there’s no ringing or layer shifts. Printed in ordinary gray Inland PLA.

To show what the AnkerMake M5C can do under less stressful conditions, I printed this Clockspring Cosmic Saucer, using Easy Mode, Normal Speed (top speed at 250mm/s) and a .2mm layer height. The pieces are printed individually and screw together.

This is remarkably smooth with crisp details and smooth walls. I printed it in Inland Dual Color Gold/Silver, Polymaker’s Starlight Jupiter (antenna) and Galaxy Dark Blue PolyLite PLA (landing gear), and Protopasta’s Cobalt Blue Translucent HTPLA (glass). Total print time is 2 hours, 30 minutes and 33 seconds.

For a practical print, I used the AnkerMake M5C to print PETG brackets to hold up a new filament shelf. I kept AnkerMake’s default settings for PETG – which restrained wall speed to 150mm/s, and beefed up the print to 6 walls and 25% infill. The top layer is a bit streaky, but the parts are still very strong. This print took 2 hours and 59 minutes to print, using IC3D recycled black PETG.

For TPU I had another practical print – caps for the end of the pipes making up my new RepRack filament shelf. I created these caps in Tinkercad, then uploaded them to Printables. Each cap took 10 minutes and 3 seconds to print using AnkerMake’s default Easy Mode settings for TPU. They printed remarkably smooth and fast with no stringing in Inland Black TPU.

Bottom Line

The AnkerMake M5C is a fast printer with some features – or lack there of – that might take some getting used to. I was concerned about the lack of a screen, but if you’re online all the time, having a phone handy isn’t really that big of an issue. You can also get around the screen issue by keeping an old mobile device with the app loaded near the printer.

One of the fastest bed slingers around, it’s definitely competitive in the current race for speedy 3D printing. With a price tag of $399 and the promise of an optional six spool “color engine” by the end of the year, the AnkerMake M5C is one to watch.

It’s dead simple to use, which makes this a great recommendation for beginners and makers who just want to make. There’s not much to tweak on this printer, so people who like to mod out their machines may want to take a pass and go build a Voron instead.

If you’re interested in other speedy printers at even higher prices, check out the blazing-fast $699 Bambu Lab P1S or the FLSun V400 Delta, a machine that is a joy to watch, but has a hefty price at $849.

If you want speed, ease AND a screen in this price range, check out the similarly priced Sovol SV07 that runs vanilla Klipper for $339. And if you’re on a really tight budget, then the Klippered Elegoo Neptune 4, priced at $259 might be just the ticket. However, at $399, the AnkerMake M5C offers a great balance of features at a reasonable price. Just keep that phone handy.

MORE: Best 3D Printers

MORE: Best Budget 3D Printing

MORE: Best Resin 3D Printers

MORE: Best 3D Printers

MORE: Best Budget 3D Printing

MORE: Best Resin 3D Printers